Pecan enthusiasts understand the delight of cracking open a fresh nut and savoring its sweet, buttery taste. Pecan crackers have become essential tools for both casual snackers and professional bakers. They offer a consistent method to shell pecans without damaging the tender nut inside. Moreover, pecan crackers come in a range of styles, sizes, and mechanisms, catering to diverse preferences and budgets.

In this comprehensive guide, we will delve into every aspect of pecan crackers, from their history and fundamental mechanics to their culinary significance and business potential. We will also provide expert tips for choosing, using, and maintaining the right tool—be it a pecan cracker, pecan sheller, or another nut cracker for pecans. Therefore, you can make informed choices, improve your shelling success rate, and ultimately enjoy tastier pecan recipes.

Whether you are a home cook or a commercial baker, knowing how to select and operate pecan crackers saves time and preserves the delicate flavor of pecans. Furthermore, with an advanced understanding of shelling tools, you will pick the best device for your skill level and intended volume. By the end of this article, you will have all the knowledge you need to elevate your pecan game.

1. A Brief History of Pecan Crackers and Pecan Shellers

Pecans have been an important food source for centuries, especially in the southern regions of North America. Indigenous communities relied on pecans for sustenance, grinding them into flour or combining them with other ingredients. However, the task of cracking pecans used to be quite laborious. Early methods involved pounding the nuts with rocks or using primitive tools that did not offer much control over the shell-cracking process.

1.1 Evolution of Pecan Shelling Techniques

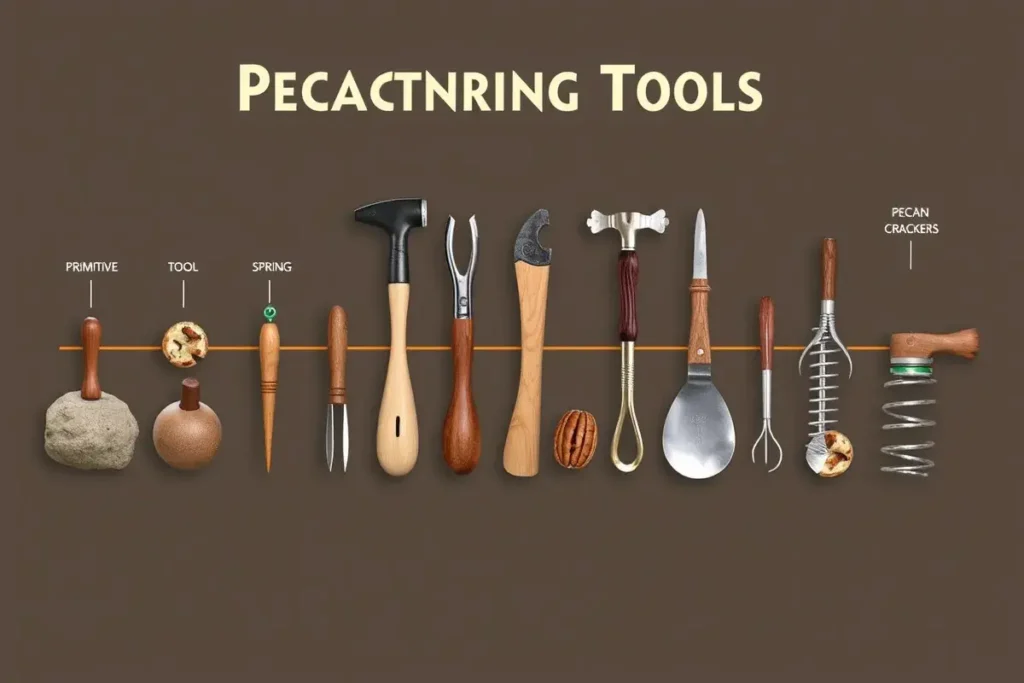

- Hand Cracking: In the earliest days, people used their hands or rudimentary rocks to break pecan shells, often damaging the kernel.

- Lever-Based Tools: By the early 1900s, metal devices that applied lever-based force made pecan cracking more efficient.

- Commercial Shelling: Mid-20th century saw the rise of large-scale machines for farms and factories, expediting the shelling process.

- Modern Pecan Crackers: Today’s pecan crackers, pecan shellers, and nut crackers for pecans range from hand-operated pliers to sophisticated, spring-loaded gadgets.

1.2 Significance of Specialized Nut Crackers for Pecans

The emergence of specialized pecan crackers and pecan shellers transformed both home and commercial nut processing. By applying controlled pressure, these devices:

- Save Time: Shell large quantities of pecans in minutes.

- Reduce Kernel Damage: Minimize broken pieces, preserving pecan halves for aesthetic dishes.

- Improve Consistency: Deliver uniform results, crucial for professional bakers and confectioners.

Therefore, having dedicated equipment for cracking pecans ensures the best possible outcome in terms of efficiency and kernel quality.

2. What Makes Pecan Crackers and Pecan Shelling Devices Stand Out

Kitchenware stores often carry generic nutcrackers alongside specialized pecan crackers. At first glance, they may seem similar. However, specialized pecan shelling devices include features tailored to manage the unique shape and brittleness of pecan shells.

2.1 Design Elements Unique to Pecan Crackers

- Adjustable Tension

- Allows precise control to crack the shell without crushing the nut.

- Ergonomic Handles

- Reduces strain on wrists during extended shelling sessions.

- Spring-Loaded Pistons

- Apply consistent force, resulting in cleaner shell breaks.

These subtle yet vital design tweaks differentiate pecan crackers from all-purpose nutcrackers. Consequently, they help ensure intact kernels and minimize shell fragments.

2.2 Why Regular Nutcrackers Fall Short

General nutcrackers are often designed with a broad approach. They apply uniform pressure that might be excessive for delicate pecans. As a result:

- Over-Cracking: Harder force can pulverize the kernel.

- Inconsistent Results: Irregular pieces instead of whole halves.

- Higher Physical Effort: Required pressure can lead to hand fatigue.

For frequent pecan lovers, opting for a tool specifically engineered for these buttery nuts will spare time and frustration.

3. Choosing the Right Pecan Crackers (Nut Cracker for Pecans) for You

Selecting the ideal pecan crackers involves considering your typical usage, budget, and comfort preferences. If you crack pecans occasionally for home baking, a simple handheld device may suffice. Yet, if you plan on processing larger volumes, a higher-end pecan sheller or nut cracker for pecans might be the smarter route.

3.1 Key Factors to Consider

- Volume of Use

- Light Usage: Handheld crackers are perfect for occasional home baking.

- Heavy Usage: Electric pecan shellers or industrial machines are best for commercial-scale output.

- Build Quality

- Materials: Stainless steel or heavy-duty plastic ensures durability.

- Construction: Look for solid hinges and minimal loose parts.

- Budget

- Entry-Level: Under $20, suitable for those who crack pecans sporadically.

- Mid-Range: $20–$60, offering better handles and adjustable features.

- High-End: Over $60, typically built for frequent or commercial shelling.

- Design & Comfort

- Ergonomic Grip: Prevents hand or wrist strain during extended use.

- Spring-Loaded Options: Offer consistent shell breakage and minimal kernel damage.

3.2 Making an Informed Decision

For casual bakers, affordable handheld pecan crackers will do just fine. However, if you shell pecans in bulk—whether for a small business or large family gatherings—investing in a more advanced pecan sheller may prove cost-effective in the long run. Therefore, determine your shelling frequency and weigh your budget before committing.

4. The Mechanism Behind Pecan Crackers and Nut Crackers for Pecans

While pecan crackers share a common goal—to break the pecan shell—the mechanical principles can vary considerably. Understanding how these devices work helps you operate them correctly and troubleshoot issues when they arise.

4.1 Common Mechanisms

- Lever Action

- A hinge-based design where you squeeze two arms together to crack the shell.

- Widely used in simpler, budget-friendly models.

- Spring-Loaded Piston

- The pecan is placed in a specialized chamber, and a piston is driven by a spring.

- Tension is often adjustable for different shell thicknesses.

- Roller Systems

- Common in industrial pecan shellers.

- Pecans pass through rollers set at a specific gap to break the shells at consistent pressure.

4.2 Steps in the Pecan Cracking Process

- Alignment: Position the pecan so that pressure targets the thickest part of the shell.

- Application of Force: Pull or press the mechanism until you hear a crack.

- Shell Removal: Gently remove broken shell fragments without damaging the kernel.

- Kernel Inspection: Ensure no shell debris remains on the nut.

Consequently, mastering these steps leads to cleaner shells and fewer shattered kernels. Furthermore, the type of cracker you use can influence how quickly you pick up these techniques.

5. Innovative Pecan Crackers and Sheller Options

Manufacturers continue to innovate designs for pecan crackers and pecan shellers. These innovations cater to the diverse needs of at-home cooks, food enthusiasts, and commercial operations.

5.1 Novel Features to Look For

- Adjustable Cracking Force: Lets you dial in the perfect pressure for different nut varieties.

- Interchangeable Parts: Accommodates various nut sizes, making the tool more versatile.

- Electric or Motorized: Automates the cracking process for rapid shelling in commercial settings.

- Built-In Shell Collection: Helps keep shells from scattering all over your work area.

5.2 Going Eco-Friendly

Many modern pecan crackers include sustainability as a design principle. For example, some feature bamboo handles or responsibly sourced metals. A tool that lasts for years also produces less waste. Therefore, an eco-friendly cracker is not only practical but also aligns with responsible consumerism.

6. Using Your Pecan Crackers: Step-by-Step Guide

Cracking pecans appears simple at first glance. However, slight adjustments in your approach can significantly improve your success rate. Below is a practical guide to using your pecan cracking tool effectively.

6.1 Preparing the Pecans

- Select Fresh Nuts: Choose pecans with intact shells.

- Optional Soak: Soaking pecans in lukewarm water for about 30 minutes can soften the shell, making it easier to crack.

- Dry Thoroughly: Make sure they are free of excess moisture to prevent slippage.

6.2 Positioning the Nut in Your Pecan Cracker

- Orient Properly: Align the pecan so the force is applied along the length of its shell.

- Avoid Overcrowding: If using a larger sheller, ensure nuts do not overlap or jam.

6.3 Cracking Technique

- Gradual Pressure: Press slowly to crack the shell rather than shatter it.

- Listen for the Snap: Stop once the shell splits.

- Remove Shell Gently: Peel away broken pieces and ensure the kernel remains intact.

6.4 Post-Cracking Tips

- Remove Shell Fragments: Even small shell pieces can affect your recipe’s texture.

- Store Properly: Keep cracked pecans in an airtight container if not using immediately.

- Clean the Cracker: Wipe down surfaces to remove oils and residue.

Hence, a little bit of patience and proper technique ensures maximum yields of beautiful pecan halves. This approach also prolongs the lifespan of your pecan cracking tool.

7. Popular Recipes That Shine with Cracked Pecans from a Pecan Cracking Tool

After successfully using your pecan crackers to achieve pristine kernels, it is time to enjoy them in a variety of dishes. Thanks to their buttery flavor, pecans enhance both sweet and savory recipes. For example, they can elevate a basic salad or transform a cookie recipe into something extraordinary.

7.1 Sweet Treats

- Classic Pecan Pie

- Key Ingredients: Pecans, corn syrup, sugar, butter, and eggs.

- Pro Tip: Lightly toast the pecans before baking for a deeper flavor.

- Pecan Pralines

- Key Ingredients: Brown sugar, heavy cream, butter, and large pecan pieces.

- Cook’s Note: Stir the mixture thoroughly to prevent burning.

- Butter Pecan Cookies

- Key Ingredients: Browned butter, chopped pecans, and vanilla extract.

- Baking Hack: Refrigerate the dough to intensify the nutty flavors.

7.2 Savory Delights

- Pecan-Crusted Salmon or Chicken

- Method: Blend crushed pecans with breadcrumbs and seasonings. Then coat the protein before baking.

- Serving Suggestion: Pair with a zesty dipping sauce.

- Pecan and Goat Cheese Salad

- Ingredients: Mixed greens, tangy goat cheese, toasted pecans, and a balsamic vinaigrette.

- Flavor Boost: Include dried cranberries or apple slices.

- Wild Rice with Pecans

- Cooking Tip: Stir toasted pecans into cooked wild rice for a nutty crunch.

- Finishing Touch: Sprinkle fresh herbs for brightness.

Therefore, fresh cracked pecans from your pecan shelling device or cracker can enrich both dessert menus and main courses. These recipes let you showcase the full potential of pecans in your culinary repertoire.

8. Caring for Your Pecan Crackers

Proper care ensures that your pecan crackers stay in prime condition. Additionally, well-maintained tools result in better nut cracking and fewer mechanical issues. Therefore, implementing a basic maintenance routine after each use is essential.

8.1 Cleaning Essentials

- Disassemble If Possible: Take apart any removable parts, especially in spring-loaded or motorized devices.

- Gentle Cleansing: Wash with mild soap and warm water. Avoid submerging electric components.

- Thorough Drying: Wipe down each component to prevent rust or bacterial growth.

- Sanitize Periodically: Use a food-safe sanitizer, especially if you frequently handle large batches of pecans.

8.2 Storage Tips

- Cool, Dry Location: Keep away from moisture and direct sunlight.

- Protect Moving Parts: Wrap or shield spring-loaded sections to prevent damage.

- Inspect Regularly: Look for worn parts or loose screws that might need tightening.

Following these simple steps will help preserve the functionality of your pecan shelling device, ensuring it remains safe, sanitary, and effective for years to come.

9. Pecan Crackers (Pecan Shelling Devices) for Large-Scale Operations

While the average home cook may only need to crack a few pecans, commercial ventures require equipment capable of processing high volumes quickly. Investing in professional pecan crackers can be transformative for businesses like pecan farms, bakeries, and candy shops.

9.1 Commercial Shelling Solutions

- Industrial Rollers

- Nuts pass through precisely spaced rollers for bulk shelling.

- Built to handle thousands of pecans per hour.

- Automated Shellers

- Conveyor systems and electric motors automate both the cracking and shell separation processes.

- Often feature adjustable settings based on nut size and shell density.

9.2 Factors to Consider for Scaling Up

- Initial Investment: Commercial machinery can range from a few hundred dollars to several thousand, depending on capacity.

- Space Requirements: Large machines need dedicated space within your facility.

- Maintenance: Advanced equipment often requires specialized service to maintain peak performance.

Therefore, although the upfront costs can be high, large-scale pecan shelling devices streamline operations and yield consistent, high-quality results. The return on investment can be significant for businesses that rely on a steady supply of perfectly cracked pecans.

10. Transforming Your Passion into a Pecan Crackers Business

If you have discovered a knack for efficiently using pecan crackers and love the taste of fresh pecans, you might consider turning this passion into a venture. Local demand for high-quality, fresh pecans can be robust, especially if you market them as hand-cracked and meticulously handled.

10.1 Possible Business Models

- Service-Oriented

- Crack-for-Others: Customers bring their nuts, and you crack them for a per-pound fee.

- Wholesale Partner: Collaborate with local growers who need ongoing cracking services.

- Product-Focused

- Packaged Pecans: Sell shelled, vacuum-sealed pecans online or at local stores.

- Value-Added Goods: Offer candied pecans, pecan pies, or pralines.

10.2 Practical Tips for Success

- Licenses & Permits: Research local requirements for handling and selling food products.

- Equipment Investment: Align your choice of pecan shelling devices with projected production volumes.

- Branding & Marketing: Emphasize the freshness and quality of your pecans.

- Customer Support: Provide transparent pricing and prompt turnaround times.

Consequently, a simple love of cracking pecans can grow into a thriving enterprise if managed effectively. Knowing how to use pecan crackers properly is just the beginning—building relationships with suppliers, perfecting your workflow, and offering unique products can also spur success.

Frequently Asked Questions about Pecan Crackers

What is the fastest way to crack pecans?

A specialized pecan cracker with a lever or spring mechanism is usually the quickest for home use. You place the pecan in the chamber, apply pressure, and the shell splits with minimal effort. However, for commercial settings, automated pecan shellers can handle vast quantities in record time.

How does a pecan cracker work?

A pecan cracker breaks the shell by applying targeted pressure, typically through a lever or spring-loaded mechanism. The key is to line up the pecan correctly and apply gradual force. Consequently, the shell cracks without severely damaging the kernel.

What is the difference between butter pecans and pecan pralines?

Butter pecans usually refer to pecans toasted or roasted in butter, often featured in ice cream and baked goods. Pecan pralines, by contrast, are confectionery treats made by coating pecans in a sugar-based syrup, resulting in a sweet, candy-like texture.

How much do people charge to crack pecans?

Rates vary depending on location, service type, and volume. Some charge per pound—ranging from $0.50 to $2.00—while others may set a flat rate for bulk cracking. Additionally, more comprehensive services that include sorting and cleaning may command higher fees.